In recent years, while steadily developing its core product, electrolytic capacitor diaphragms, KAN New Materials has made new strategic deployments and implemented a "two legged" business development strategy. On the basis of locking in the world's largest producer of electrolytic capacitor diaphragms, Kane New Materials has vigorously developed filter paper products, focusing on building the company's second ace and launching an attack towards establishing the world's largest filter paper product production base. After more than a decade of strategic layout, technical and sales team efforts, the sales of the company's tea filter paper product series have shown a continuous growth trend. While the new high-end filter paper production line is successfully put into operation this year, in order to achieve the company's next goal, two efficient filter substrate production lines will be launched in the near future to alleviate the bottleneck of insufficient filter paper production capacity.

Russia is a key region for global tea bag production and is naturally a battleground for global filter paper manufacturers. In order to further strengthen the overseas market, from November 9th to 17th, the General Manager of the company, Liu Chengyue, led a sales team to Russia, visited several key Russian tea bag production enterprises, comprehensively understood market trends, and conducted business cooperation negotiations. On the basis of mutual benefit, we reached long-term cooperation agreements with key customers, became strategic partners, locked in production orders for 2024, and laid a good foundation for the next step of development.

In the current environment of fierce market competition, oversupply, and continuous decline in overall prices of foreign paper products, the company has sharpened its sword for decades, improved product technology and quality, and successfully promoted the overseas market, which is not easy. This fully demonstrates the company's strong strength and the full recognition and trust of its partners.

Kan has accumulated nearly 20 years of experience in the research, development, and production of filter paper series products. As a special type of paper, tea filter paper has extremely high performance and quality requirements in terms of breathability, water filtration performance, wet strength, and heat sealing performance indicators. Due to the particularity of the filter paper series products, there are also strict restrictions on production management software and hardware. If a food related product production license is required, in order to promote it to the international market, it is also necessary to pass the BRCGS Global Standard for Packaging Materials certification. After testing, our company's products meet the regulatory requirements of GB4806.8 "Paper and Paperboard Materials and Products for Food Contact", FDA 176.170 for food contact paper in the United States, and the European Union.

The successful expansion of the company's overseas market fully demonstrates the company's management strategy and sales team's keen market sense. As soon as the Russo Ukrainian war broke out last year, the company's sales team keenly caught the opportunity and contacted the Russian manufacturer for negotiations, seizing the opportunity to cooperate and laying a solid foundation for this year's deep and long-term cooperation.

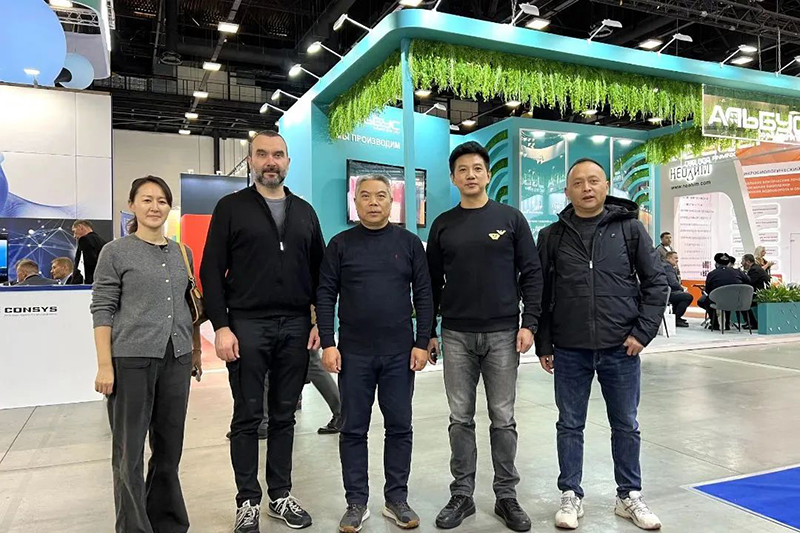

During their visit to Russia, the Kan team also visited the Russian Paper Expo in St. Petersburg to learn about the development trends of the Russian wood pulp and paper industry, and to enhance understanding, communication, and relationships with cooperative clients.

During this trip to Russia, the Kan team has achieved fruitful results. We believe that this battle will bring new and greater development opportunities for the company's filter paper products. Kan's "two legged walk" will also be more solid and vigorous.